Bienvenidos a Langfang-bonai

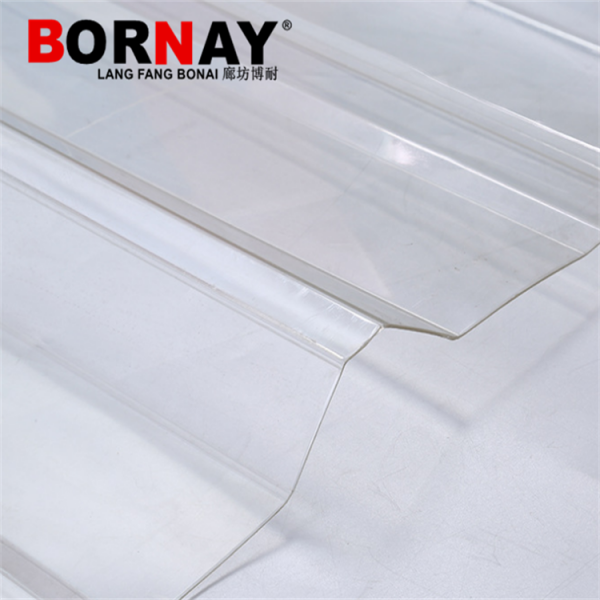

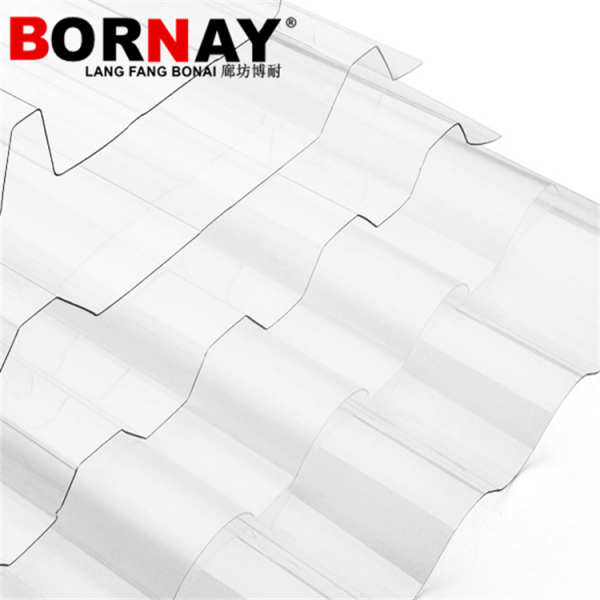

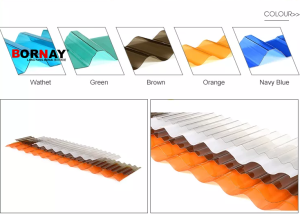

Placa corrugada de policarbonato

Descripción

Product Introduction:

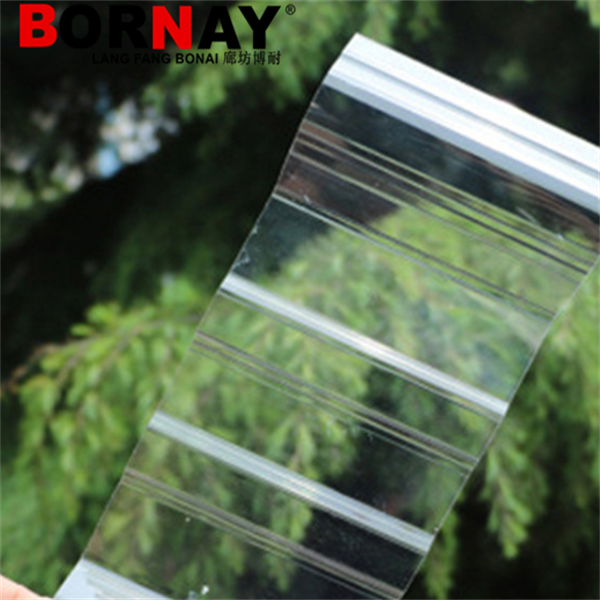

Langfang Bonai PC corrugated tile is made of new polycarbonate as raw material, without adding any back material, it has the same transparency as glass, and the hardness is dozens of times that of glass

Características:

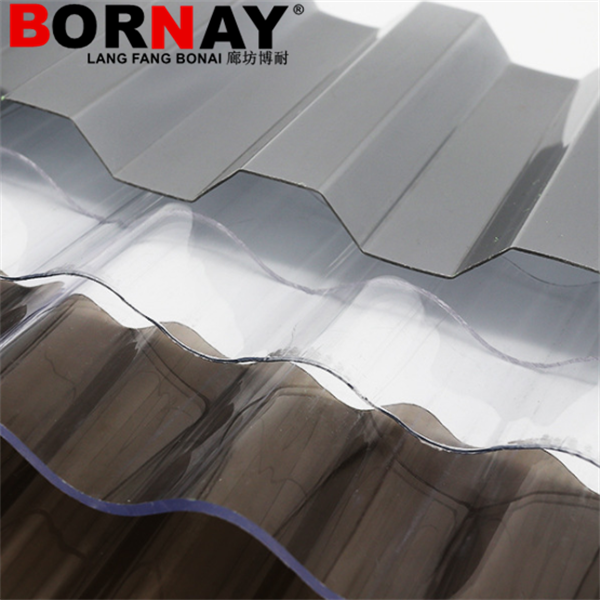

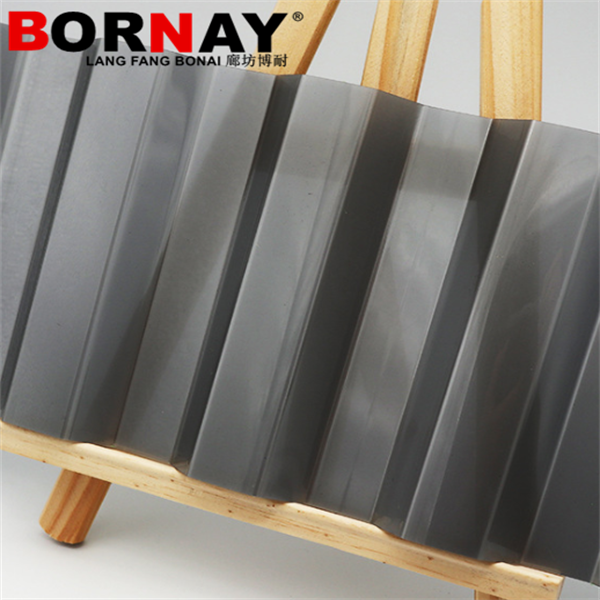

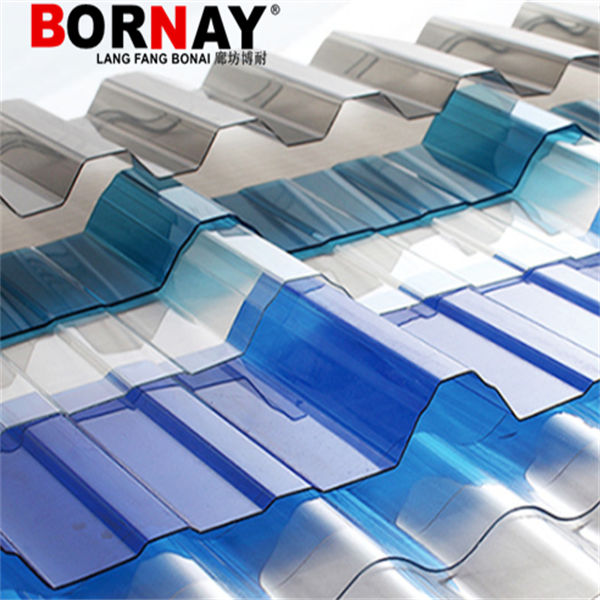

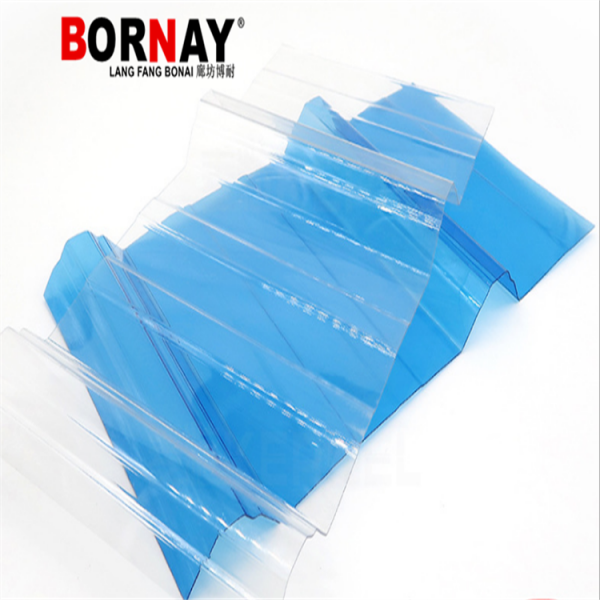

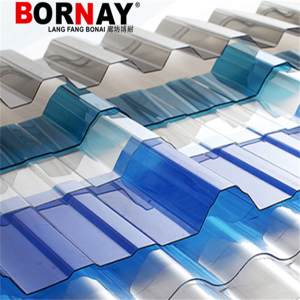

> Rich colors, durable

> Service temperature is -40°----+ 120° >Fire retardance: Grade B1,and Sound insulation and Light weight >Light transmittance rate up to 12%-88%,according to to different colors

> Ultraviolet ray filter rate: 9 9 % , with ultraviolet- resestant co- extruded film on the surface

>Impact strength: 250-280 times of the ordinary glass;4 times of toughened glass;20-30 times of PMMA sheet

Application:

> Various types of building roof decoration

> Roofs with fire and corrosion resistance requirements >Factory buildings, sun rooms, greenhouses

Detail:

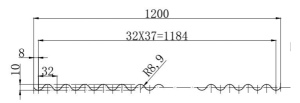

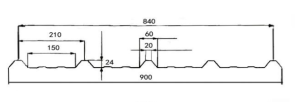

Thickness:0.8mm--2.5mm Length : customized

Installation Method:

>PC corrugated roof tile is paved on the structural roof

> Lap a wave horizontally Longitudinal overlap section

> Use special supporting installation components

>The screw is tight and tight when fixing

LANGFANG BONAI EP TECH CO.,Ltd. was established in 2008, covers an area of 15,000 square meters, has an investment of 12 million, and has 76 employees, including 3 R&D personnel. In 2010, it introduced two FRP continuous production lines and 3 antique tile production lines from Australia. 2 PC production lines, with an annual output value of more than 80 million Address: Gongcun, Dacheng county, Langfang City, China. Mobile :0086 18931685668 Email : bonai@tilefrp. com

Notice on Installation and Use of Polycarbonate (PC) Plate

1、 Fixed

1.1 The diameter of the nail head of the fixing nail shall be more than 1.5 times larger than the diameter of the screw handle, and waterproof film or aluminum alloy strip shall be applied. Do not press the nail head directly against the plate surface to reduce the pressure.

1.2 The upper screw shall not be too tight, or it may cause stress and local cracks on the plate surface.

1.3 The waterproof film shall not use PVC rubber mat or asphalt waterproof tape; The sealant must be neutral silicone weather resistant sealant, and acid sealant is not allowed.

1.4 In the installation process, it is not allowed to fix both ends first and then fix the middle. One end should be fixed first and the construction should be carried out along the same direction, otherwise the middle stress concentration will be caused, which will lead to product deformation or cracking.

1.5 Since the linear expansion coefficient of PC board is about 6-7 times larger than that of metal materials, the holes must be drilled on the PC board before fixing with tapping screws, and the tapping screws must be placed in the middle of the hole diameter, otherwise the PC board around the tapping screws will crack or the board surface will shrink and deform due to insufficient displacement during thermal expansion and cold contraction.

1.6 Calculation of reserved expansion space: Expansion value=linear expansion coefficient X maximum temperature change value of length Linear expansion coefficient of PC board=7x10-5mm/mm/C For example, for a PC board with a length of 1000mm, if the annual maximum temperature difference is 30C, the reserved expansion space=7x10-5 (mm/mm/C) x1000 (mm) x30 (C)=21mm, so the reserved expansion space must be at least 21mm. For example, if a 5mm self tapping screw is used, the diameter of the pc board hole must be greater than 7.1mm

1.7The Dc board attachment surface on the metal frame must be absolutely flat. It is better to use butyl waterproof tape as the backing.

1.8 Since the linear expansion coefficient of PC board is about 6-7 times larger than that of metal materials, the length of single board surface must be less than 6m when installing the board Avoid cracking due to excessive stress caused by thermal expansion and cold contraction.

1.9 No screws shall be drilled within 20mm from the edge of the plate.

1.10 The sunlight plate shall be bent along the direction of the auxiliary reinforcement, and the bending radius shall be greater than 175-200 times of the plate thickness. Screw fixation is not allowed in the bending part of the plate. (Refer to the technical manual for specific bending radius)

1.11 When installing the solar panel, the protective film with characters on the panel shall be installed facing the outside. After installation, the protective film shall be removed immediately to avoid adhesion between the protective film and the solar panel after exposure to the sun. The cutting length of 112pc plate must be greater than the width before bending.

2、 Cleaning

The dust and dirt on the surface of PC board shall be wiped with soft cloth or sponge dipped with neutral detergent, and then washed thoroughly with clean water

3、 Chemical corrosion

3.1 It is forbidden to contact with cement floor, acid and alkaline materials. 3.2 It is prohibited to dissolve with organic solvents such as benzene, gasoline, carbon tetroxide, tiana water, turpentine, or glue and paint containing such components

4、 The manufacturer will not be responsible for any plate crack after installation in violation of the above operating regulations, and will not assume relevant responsibilities

CHARACTERISTICS

| Atributos | Detalles |

| Tela | Policarbonato |

| Marca | Langfang Bonai |

| Largo | 11,8m / 1,6m / 5,8m / 2,9m o Personalizado |

| Ancho | Pattern width or customized |

| Grueso | 0.5mm–2.0mm |

| Color | Transparente, azul, verde, blanco, rojo, amarillo, etc. o Personalizado |